Eddy Current

Description of Eddy Current Testing

Eddy current is an electromagnetic technique and is completely non-destructive. It works on the principles of Electro Magnetic induction. There is no dangerous radiation or hazardous chemicals involved with this technique.

We specialize in the inspection of installed heat exchanger tubing used in:

- Commercial Air Conditioning

- Power Industries

- Pulp Industries

- Chemical Industries

Eddy Current is limited to testing metallic materials and works best on non-magnetic alloys. It can be applied to magnetic materials, such as Monel, Nickel, Ferralium or other Ferritic Stainless steels using magnetic saturation techniques.

How Inspections are Performed

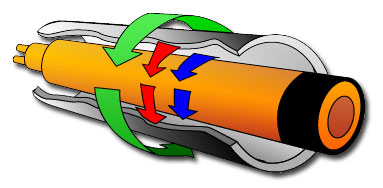

Our specially trained technicians insert an inspection probe down the full length of each tube being inspected and observing the eddy current response on the test instrument screen. Coils located in the inspection probe produce an electromagnetic field which are effected by changes in the tube wall such as wall loss and pitting.

TAI Services uses a computerized multi-channel, multi-frequency eddy current test system, with mixer capabilities. Typical inspections are performed using both a Cross Axial or Absolute and a Differential channel displayed simultaneously.

Cross Axial coil configurations are primarily used for the inspection of finned tubing. They are specially designed for the detection of transverse, or radial cracks, which can develop in the transition zones of finned tubes.

Differential coil configurations consist of two narrow wound coils which produce an eddy current flow around the circumference of the tube in a narrow path. This results in a high resolution detection for small pits and inclusions. This type coil arrangement cancels out gradual changes in the tube wall making it possible to detect and accurately measure pitting in areas of wash out using phase analysis.